Let’s be honest… Chip is a perfectionist and when he does anything…he goes ALL OUT! That was certainly the case when we decided to build a to-scale model of Pinhoti. Having a scaled model of the home not only helps us visualize the details, but also helps us communicate our construction techniques, innovative spatial planning, and intricate details that makes this house so amazing!!

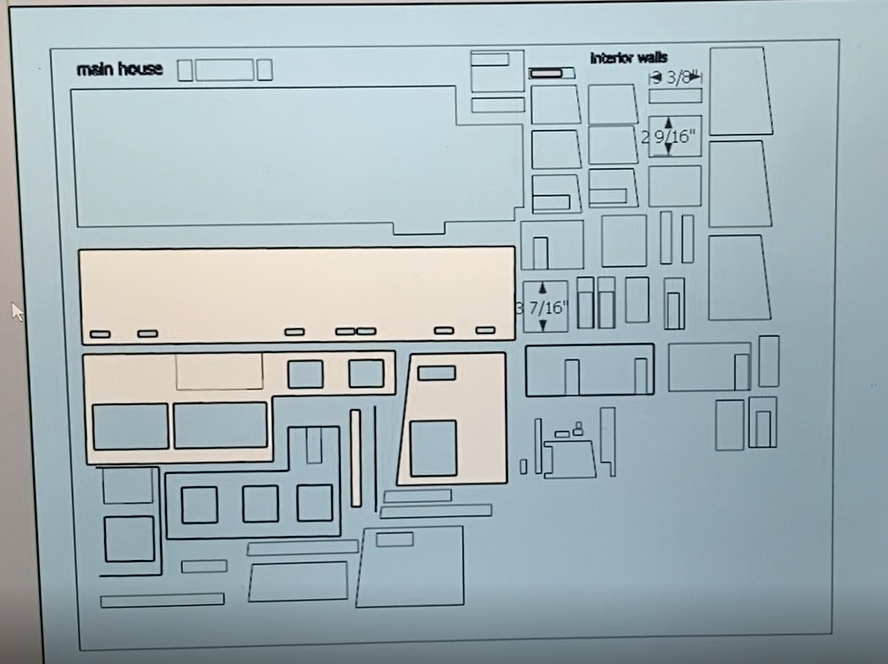

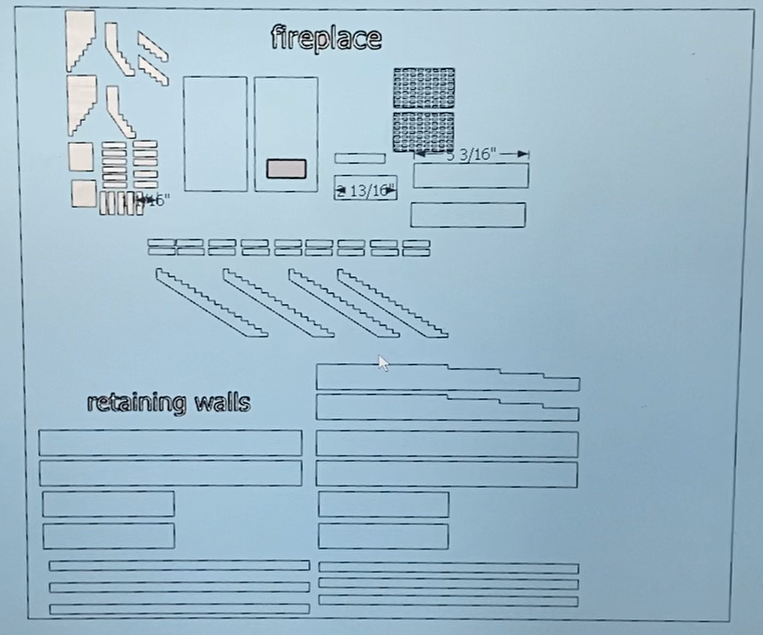

The building of the model started with creating a cut file from our SketchUp model. Essentially the 3D model had to be flattened and analyzed to create the accurate outlines for the laser printer. This part of the process took several hours of detailed review!

One we had the pieces, it was time to assemble! This was an entire family affair. Chip and I recruited the help of both our sets of parents and Chip’s sister, Dena. I wish that it went as fast as the time lapse, but it took about 2 full days to complete the assembly. The RapidFuse gel adhesive from DAP was a critical component of the model coming together quickly, relatively…I mean if we had to wait 24 hours for each bond to dry this would have taken months!

But in the end, it was all worth it…and Mara has claimed it to be her doll house once we are finished using it for the project!

Looks great – would love to follow your progress, if you are sending out updates please include me on the list. I especially like the type of construction and would like to know more about the appliances, and home products you are using. Note I am not a builder but am in the process of considering new construction in Angel Fire, NM for my family.

what is a good choice for flooring kitchen foyer hall way, bath rooms.

what is the best choice for flooring kitchen foyer hall way, bath rooms.